CORE-BOND / Reflow Core

The Science Behind the Bond

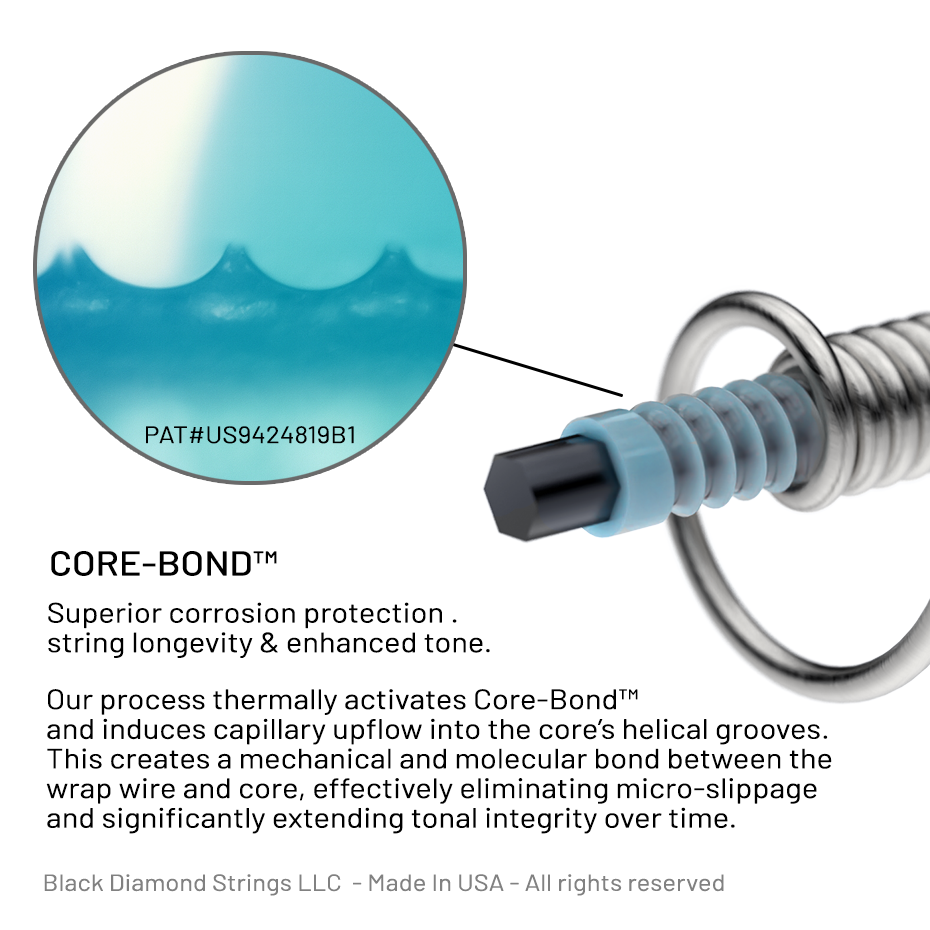

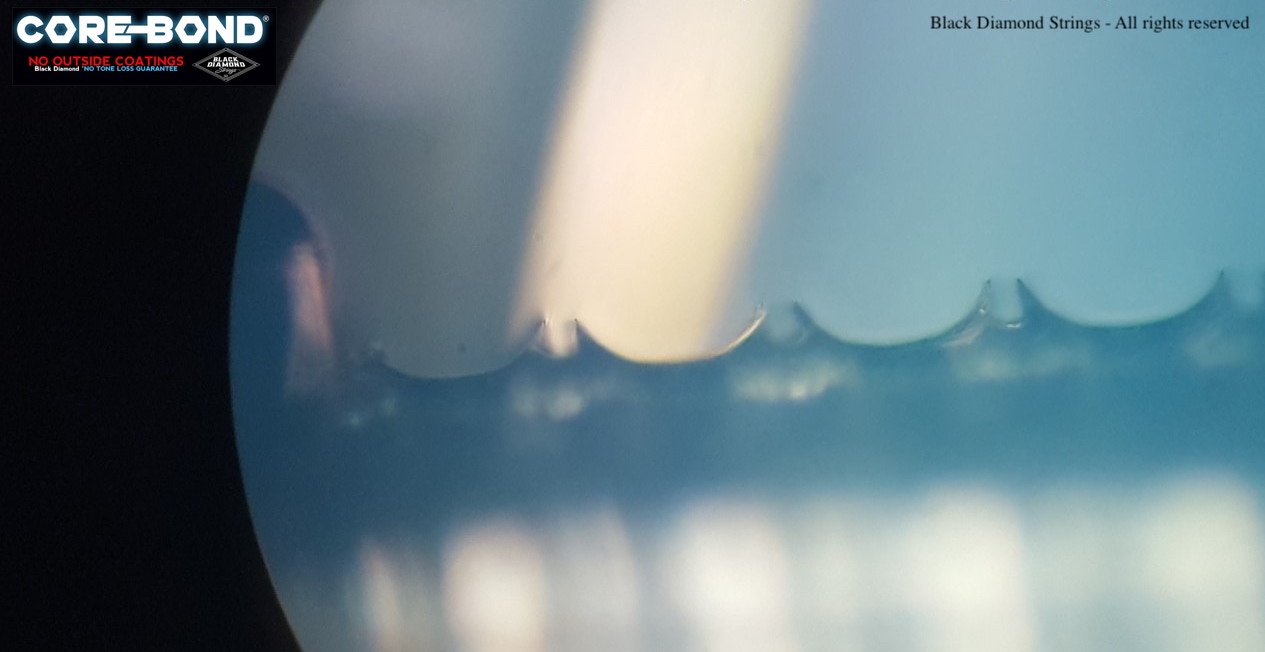

In the magnified image above—with the outer wrap wire removed—you can see the high-carbon steel core and the precision-engineered valleys formed by our exclusive Core-Bond™ technology.

During our secondary flow process, Core-Bond™ is liquefied and pressure-infused into these microscopic grooves, creating a permanent mechanical and chemical lock between the core and wrap wire.

This bond doesn’t just hold—it protects. The core is now sealed from the inside out, shielded from galvanic corrosion and tone-killing slippage that often plagues traditional strings.

The result? Longer life, consistent tone, and unmatched durability—powered by the precision of Core-Bond™.

LEADING BRANDS OUTER COATING

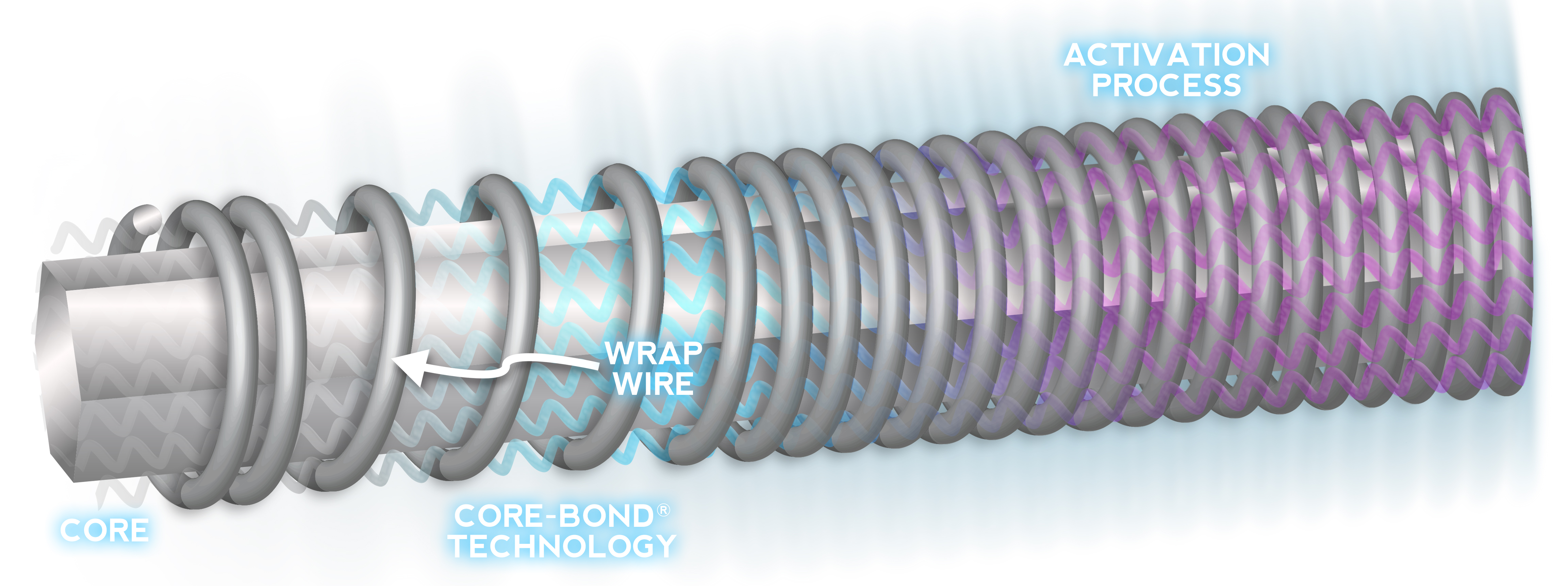

This is how Core-Bond™ works...

The Core of the Problem — Solved

As a wound string is tuned to pitch, the core wire naturally stretches and slightly thins, while the wrap wire remains unchanged. To compensate, most string makers apply the wrap under simulated tension—but over time, it’s not enough.

With regular use, vibrations continue to thin the core, allowing the wrap to shift or slip, which compromises the coupling between core and wrap. This is one of the leading causes of tone loss—and corrosion accelerates the problem.

Core-Bond™ Technology changes everything.

By permanently bonding the wrap wire to the core, the coupling remains stable and intact, dramatically extending tone life and string performance—often beyond anything previously possible.

But we didn’t stop there.

Tuning stability, string strength, and even the twist-lock at the ball end are all reinforced through the Core-Bond™ process. Once activated, the ball-end twist becomes virtually unbreakable—locked and bonded into place for unmatched reliability.

With Core-Bond™, your strings stay strong, stable, and full of life—long after others go dead.

WE’VE CHANGED THE GAME — FROM THE INSIDE OUT

Coated vs. Non-Coated Core-Bond™ Testing in Ocean Water

While traditional coated strings rely on surface protection that can wear away, Core-Bond™ technology defends your strings from within. Our rigorous testing in harsh ocean water conditions proves how Core-Bond™ outperforms coatings by locking the wrap and core together—resisting corrosion and tone loss far longer.

Extreme Testing, Extraordinary Results

We put Core-Bond™ strings to the ultimate test—submerging them in a 5% saline bath, simulating harsh ocean water conditions for 96 hours. And remember, these Core-Bond™ strings have no outer coating for protection.

The results speak for themselves.

While we know players won’t be dunking their strings in ocean water, this test powerfully demonstrates the superior internal protection Core-Bond™ provides.

The image below shows the ends of the strings clipped to expose the steel-plated core wire—where corrosion usually starts fast. Notice the corrosion seeping through the center of the coated string on the right, while the Core-Bond™ string on the left shows no such damage.

This is real proof that Core-Bond™ technology locks in durability and defies corrosion—even under extreme conditions.

Now, we realize a player is not going to put their string in ocean water, but this does validate the protection characteristics of Core-Bond ™️

The strings were clipped at each end to show the acceleration of corrosion at the ends of the exposed steel-plated core wire. Notice seepage of corroded core coming through the center of the coated string on the right, compared to the non-outer coated Core-Bond ™️ treated string left.

PATENT - US9424819B1 - Corrosion-resistant wound musical string. Abstract - The method improves the core wire-to-wrap wire bond by using a bond coating between the core and wrap wires that preferably also minimizes the galvanic activity between them. The bondable coating is applied to the core or wrap wires, or both. In one embodiment the method entails creating a coated core wire by annealing bare core wire, bathing the bare core wire in a bondable coating material and removing any excess, drying the bondable coating, making the string using the bondable-coated core wire, and reflowing the bondable coating. In another embodiment the method entails additionally coating the wrap wire with a coating that does not reflow under the same conditions as the bondable coating on the core wire, and winding the coated wrap wire around the bondable-coated core wire before reflowing the bondable coating.

COPYRIGHT 2018 - Core-Bond ™️ by Sfarzo Guitar String Company LLC - IMAGES AND WRITTEN CONTENT USE ON THIS WEBSITE MAY NOT BE REPRODUCED WITHOUT WRITTEN PERMISSION AND CONSENT - CONTACT: INFO@BLACKDIAMONDSTRINGS FOR GRANTED PERMISSION